InfrastructureSelf-compacting concrete is now fire resistant as well

Self-compacting high-performance concrete (SCHPC) has till now suffered from one weakness — when exposed to fire it flakes and splits, which reduces the loadbearing capacity of ceilings, walls, and supporting pillars, thus increasing the risk of collapse in a burning building. Scientists have now developed a method of manufacturing fire resistant self-compacting high-performance concrete which maintains its mechanical integrity under these conditions.

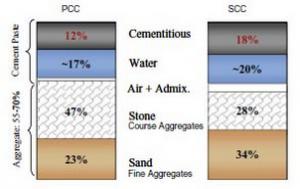

Comparison of components in concrete types // Source: dot.gov

Self-compacting high-performance concrete (SCHPC) has till now suffered from one weakness — when exposed to fire it flakes and splits, which reduces its loadbearing capacity. Scientists at the Swiss Federal Laboratories for Materials Science and Technology (EMPA) have now developed a method of manufacturing fire resistant self-compacting high-performance concrete which maintains its mechanical integrity under these conditions.

Wood crackles as it burns in a chimney or campfire. When concrete is exposed to fire it chips and flakes — a process known as spalling. Both effects are due to the same phenomenon: water trapped within the piece of wood or concrete element vaporizes due to the high temperature. As more water vapor is produced the pressure within the wood or concrete structure increases. In wood this causes the cells to burst with a crackling sound, creating cracks in the logs. In concrete structures, chips split away from ceilings, walls, and supporting pillars, reducing their loadbearing capacity and increasing the risk of collapse in a burning building.

The resistance of conventional vibrated concrete to the heat of a fire can be optimized by adding a few kilograms of polypropylene (PP) fiber per cubic meter of concrete mixture. When exposed to fire the fibers melt, creating a network of fine canals throughout the concrete structure. These allow the water vapor to escape without increasing the internal pressure, so the concrete structure remains intact.

Fire resistance vs self-compacting ability

Self-compacting high-performance concrete (SCHPC) behaves differently, though. Adding more than two kilograms of PP fiber per cubic meter to the SCHPC mixture affects its ability to self-compact, so the proportion of PP fiber in SCHPC must be kept relatively low. This in turn means that if the concrete is exposed to fire, the network of fine canals created by the melting fibers is not continuous throughout the entire structure, allowing spalling to occur. The $64,000 question is, therefore, how to make SCHPC fire resistant, so buildings made of it are safer, whilst keeping the proportion of polymer fibers low enough that the concrete remain self-compacting.

EMPA reports that researchers from EMPA’s Concrete / Construction Chemistry and Mechanical Systems Engineering Laboratories have now managed to find an answer. They manufactured a series of thin-walled concrete slabs which were pre-stressed with cables made of carbon fiber reinforced polymer. The concrete from which the slabs were made also contained two kilograms of PP fiber per cubic meter of mixture. In some slabs the scientists also added a small quantity of super absorbing polymer (SAP), a special synthetic material which is capable of absorbing many times its own weight in water. They then exposed the concrete slabs to fire, reaching temperatures of up to 1000°C. After ninety minutes it became clear that while the SAP-containing concrete slabs showed some minor cracking, spalling occurred only in the SAP-free slabs.

The explanation for this behavior is this: during the manufacturing process the SAP is saturated with water, swelling to several times its dry volume. As the concrete is setting the water is drawn out of the SAP by capillary action in the porous cement matrix. The SAP shrinks and creates hollow spaces which link the individual, hitherto unconnected networks of PP fibers. The result is a dendritic network of SAP and PP fibers which permeate the entire volume of concrete, allowing it to tolerate the heat of the fire for sufficiently long to maintain the structural integrity of the building.

Possible applications for fire resistant self-compacting concrete

With their innovative development the EMPA researchers have widened the opportunities for exploiting the economic and environmental advantages offered by self-compacting concrete (SCC). The new process, for which a patent has been applied, allows for instance the use of SCHPC for fire resistant structures. To date this is only been possible using SCC in combination with a sprinkler extinguishing system or an external thermal insulation layer.

EMPA notes that the new SCHPC boasts an additional advantage: the machines used to compact conventional vibrated concrete generate a considerable amount of noise. Construction companies can now keep the noise level down by using SAP enriched self-compacting high-performance concrete instead of vibrated concrete, without any loss of fire resistance.