-

Using UV light to separate rare earth metals

Europium and yttrium are two rare earth metals that are commonly used in sustainable technology and high-tech applications. As these rare earth metals are difficult to mine, there is a great interest in recycling them. Researchers have discovered a method to separate europium and yttrium with UV light instead of with traditional solvents. Their findings offer new opportunities for the recycling of fluorescent lamps and low-energy light bulbs.

-

-

Nepal should use updated, upgraded building codes in post-disaster construction: Experts

Urban planners and disaster experts who have been arriving in Kathmandu to inventory, assess, and make recommendations have been urging the Nepalese authorities to “Build it back better.” There are plenty of examples of post-disaster construction built significantly safer, using low-cost traditional materials and methods. Nepal has last updated its building code in 1994.

-

-

Structures tougher than bulletproof vests

Researchers have created new structures that exploit the electromechanical properties of specific nanofibers to stretch to up to seven times their length, while remaining tougher than Kevlar. These structures absorb up to 98 joules per gram. Kevlar, often used to make bulletproof vests, can absorb up to 80 joules per gram. Researchers hope the structures will one day form material that can reinforce itself at points of high stress and could potentially be used in military airplanes or other defense applications.

-

-

A surprising source of valuable metals, critical elements: Sewage

More than seven million tons of biosolids come out of U.S. wastewater facilities each year. About half of that is used as fertilizer on fields and in forests, while the other half is incinerated or sent to landfills. Researchers say that poop could be a goldmine — literally. Surprisingly, treated solid waste contains gold, silver, and other metals, as well as rare elements such as palladium and vanadium which are used in electronics and alloys. The researchers are looking at identifying the metals that are getting flushed and how they can be recovered. This could decrease the need for mining and reduce the unwanted release of metals into the environment.

-

-

Future supply risks threaten metals used in high-tech products

During the past decade, sporadic shortages of metals needed to create a wide range of high-tech products have inspired attempts to quantify the criticality of these materials, defined by the relative importance of the elements’ uses and their global availability. In a new paper, a team of researchers assesses the “criticality” of all sixty-two metals on the Periodic Table of Elements, providing key insights into which materials might become more difficult to find in the coming decades, which ones will exact the highest environmental costs — and which ones simply cannot be replaced as components of vital technologies.

-

-

Damage-sensing, self-repairing concrete

Skin is renewable and self-repairing — our first line of defense against the wear and tear of everyday life. If damaged, a myriad of repair processes spring into action to protect and heal the body. Clotting factors seal the break, a scab forms to protect the wound from infection, and healing agents begin to generate new tissue. Taking inspiration from this remarkable living healthcare package, researchers are asking whether damage sensing and repair can be engineered into a quite different material: concrete. Their aim is to produce a “material for life,” one with an in-built first-aid system that responds to all manner of physical and chemical damage by self-repairing, over and over again.

-

-

Recycling valuable rare earth metals from old electronics

Rare earth metals are valuable ingredients in a variety of modern technologies and are found in cell phones, hard disk drives in computers, and other consumer electronics, which are frequently discarded for newer and more up-to-date versions. U.S. consumers disposed of 3.4 million tons of electronics waste in 2012. Continuously increasing global demand for new consumer electronics in turn drives demand for rare-earth metals, which are difficult and costly to mine. Scientists have developed a two-step recovery process that makes recycling rare earth metals easier and more cost-effective.

-

-

Overcoming problems, risks associated with rare earth metals

Numerous metallic elements – called rare earth materials — are regarded as critical: they play an ever more important role in future technologies, but there is a high risk of supply bottlenecks. Small and medium-sized companies are also affected by this, and they are often not sure which of these materials they are dependent on. A recent event at the Swiss Federal Laboratories for Materials Science and Technology (EMPA) aimed to demonstrate ways in which industry and the research community can counter supply risks and the consequence of the ever greater use of these raw materials.

-

-

Concrete solutions to aging, structurally deficient bridges

According to the Pennsylvania Department of Transportation (PennDOT), the state leads the nation in the number of bridges classified as “structurally deficient.” This is probably not a surprise to most residents who have done any driving throughout the commonwealth. The state’s more than 25,000 state-owned bridges are aging — their average age is over fifty years — and in need of repair. Penn State civil engineering faculty are researching methods for enhancing the maintenance and durability of civil infrastructure — including anything made of concrete, from bridges to roads to buildings.

-

-

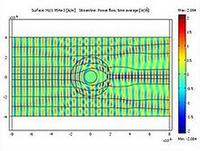

Invisibility cloak closer to reality: Concealing military airplanes, and even people

Since the beginning of recorded time, humans have used materials found in nature to improve their lot. Since the turn of this century, scientists have studied metamaterials, artificial materials engineered to bend electromagnetic, acoustic, and other types of waves in ways not possible in nature. Now, Hao Xin, a professor of electrical and computer engineering at the University of Arizona, has made a discovery with these synthetic materials that may take engineers one step closer to building microscopes with superlenses that see molecular-level details, or shields that conceal military airplanes and even people.

-

-

Ionic liquids hold promise for better rare-earth materials processing

Scientists at the U.S. Department of Energy’s Ames Laboratory and Critical Materials Institute are harnessing the promising qualities of ionic liquids, salts in a liquid state, to optimize processes for critical materials. Ionic liquids have a lot of useful qualities, and these liquids can be engineered with specific functions in mind. One such function is improving the rare-earth separation process, either for extracting rare earths from ore or recycling rare earths from discarded magnets.

-

-

Micro-capsules and bacteria used in self-healing concrete

Researchers are aiming to develop a novel self-healing concrete that uses an inbuilt immune system to close its own wounds and prevent deterioration. Self-healing concrete could vastly increase the life of concrete structures, and would remove the need for repairs, reducing the lifetime cost of a structure by up to 50 percent. Over seven per cent of the world’s CO2 emissions are caused by cement production, so reducing the amount required by extending the lifetime of structures and removing the need for repairs will have a significant environmental impact.

-

-

Invisibility cloaks, stealth technology a step closer

It may seem easy in Hollywood movies, but is hard to create invisibility cloaks in real life because no material in nature has the properties necessary to bend light in such a way. Scientists have managed to create artificial nanostructures that can do the job, called metamaterials. The challenge, however, has been making enough of the material to turn science fiction into a practical reality.

-

-

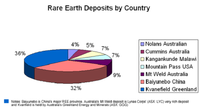

China's share of rare earths minerals declining amid falling demand

China still dominates the world’s rare earth elements market, but its share in global production has been steadily decreasing in recent years. A new study which shows a dramatic decline in these minerals’ prices has shaken he industry. In 2013, China accounted for 92.1 percent of high-tech rare earth oxides produced in the world. The percentage is still high, but it is a decline from 2010, when China accounted for 97.6 percent of global production of the mineral and fell to 95.1 percent in 2011.

-

-

Value of U.S. mineral production decreased in 2013

Last year, the estimated value of mineral production in the United States was $74.3 billion, a slight decrease from $75.8 billion in 2012. According to the U.S. Geological Survey’s annual Mineral Commodity Summaries 2014 report, the 2013 decrease follows three consecutive years of increases. Net U.S. exports of mineral raw materials and old scrap contributed an additional $15.8 billion to the U.S. economy.

-

- All

- Regional

- Water

- Biometrics

- Borders/Immig

- Business

- Cybersecurity

- Detection

- Disasters

- Government

- Infrastructure

- International

- Public health

- Public Safety

- Communication interoperabillity

- Emergency services

- Emergency medical services

- Fire

- First response

- IEDs

- Law Enforcement

- Law Enforcement Technology

- Military technology

- Nonlethal weapons

- Nuclear weapons

- Personal protection equipment

- Police

- Notification /alert systems

- Situational awareness

- Weapons systems

- Sci-Tech

- Sector Reports

- Surveillance

- Transportation

Advertising & Marketing: advertise@newswirepubs.com

Editorial: editor@newswirepubs.com

General: info@newswirepubs.com

2010-2011 © News Wire Publications, LLC News Wire Publications, LLC

220 Old Country Road | Suite 200 | Mineola | New York | 11501

Permissions and Policies

Editorial: editor@newswirepubs.com

General: info@newswirepubs.com

2010-2011 © News Wire Publications, LLC News Wire Publications, LLC

220 Old Country Road | Suite 200 | Mineola | New York | 11501

Permissions and Policies