-

Man-induced quakes to help in building safer, sturdier buildings

A team led by Johns Hopkins structural engineers is shaking up a building in the name of science and safety. Using massive moving platforms and an array of sensors and cameras, the researchers are trying to find out how well a two-story building made of cold-formed steel can stand up to a lab-generated Southern California quake.

-

-

Motivating businesses to adopt building resiliency standards

Increased resilience for buildings in the face of hurricanes, earthquakes, terrorism, or cyberattacks has been a major national security focus over the past decade. Such resilient buildings not only would be less susceptible to damage and work interruption but could become community gathering places in a general crisis. It will not be easy, however, to secure voluntary adoption of resiliency standards by industry and builders without adequate justification.

-

-

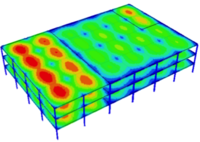

Testing the seismic strength of light frame steel construction

A partnership of leading earthquake engineering researchers from top U.S. and Canadian universities and design professionals from the steel industry have begun the final phase of a three-year project to increase the seismic safety of buildings that use lightweight cold-formed steel for their primary beams and columns. Research to conclude with shake-table testing.

-

-

Studying rare Earth elements in Alaska may help make them less rare

A unique deposit of heavy rare Earth elements (REE) at Alaska’s Bokan Mountain could help scientists understand how rare Earth element deposits form, according to new research. Rare Earth elements are important, but scarce, elements used in components in many cutting edge electronic and defense technologies.

-

-

New technology prevents bridge collapse

Researchers propose a new technology that could divert vibrations away from load-bearing elements of bridges to avoid catastrophic collapses. The researchers propose a “wave bypass” technique that has many similarities to those being used by researchers looking to create Harry Potter-style invisibility cloaks, which exploit man-made materials known as metamaterials to bend light around objects.

-

-

Ash from olive residue biomass leads to more effective, cheaper concrete

Researchers have produced self-compacting concrete with ash from boiler combustion of olive pruning residue pellets. The plasticity and cohesion of this type of concrete mean no compaction is needed when used in construction and, moreover, it has other advantages with respect to conventional concrete.

-

-

U.S. policy may lead to growing global shortage of helium

Helium is an essential resource in technologies such as medical imaging, rocket engines, and surveillance devices. In response to the element’s scarcity, the United States has been stockpiling helium since the 1960s in a National Helium Reserve called the Bush Dome, a deep underground reservoir outside of Amarillo, Texas. In 1996 the Helium Privatization Act mandated that the Department of the Interior sell off all the stockpiled helium by 2015. Scientists say that this action discourages the active exploration of helium since companies can buy it from the United States at a cheap price and sell it at a premium. The result will be a growing shortage of helium.

-

-

Making concrete “greener”

Many factors determine the overall energy and environmental impact of concrete. Reducing the amount of portland cement, which reacts with water to bind all the sand, stone, and the other constituents of concrete as it hardens, provides the biggest opportunity. Portland cement manufacturing accounts for more than 5 percent of U.S. industrial carbon-dioxide emissions. In addition, the U.S. cement industry consumes 400 gigajoules of energy annually.

-

-

Building stronger, greener concrete with biofuel byproducts

The world uses nearly seven billion cubic meters of concrete a year, making concrete the most-used industrial material after water. Even though making concrete is less energy intensive than making steel or other building materials, we use so much of it that concrete production accounts for between 3 to 8 percent of global carbon dioxide emissions.

-

-

Precious metal recovery technique ideal for rare Earth elements purification

Researchers have come up with a new approach to make the recovery of high value precious metals faster and more economically viable. The new technique could be ideal for the purification of rare earth elements, which are vital commodities for ‘green’ technologies such as hybrid cars and novel batteries.

-

-

New source for rare earth elements: discarded consumer products

In a new twist on the state’s mining history, a group of Idaho scientists will soon be crushing consumer electronics rather than rocks in a quest to recover precious materials. Two national labs in the state will apply expertise gained in recycling fissionable material from nuclear fuel to separate rare earth metals and other critical materials from crushed consumer products.

-

-

Self-healing protective coating for concrete

Scientists are reporting development of what they describe as the first self-healing protective coating for cracks in concrete, the world’s most widely used building material. The coating is inexpensive and environmentally friendly.

-

-

New internally cured concrete increases bridge life span

Concrete is normally made by mixing portland cement with water, sand, and stone. In the curing or hardening process, water helps the concrete mixture gain strength by reacting with the cement. Traditionally, curing is promoted by adding water on top of the bridge deck surface. The new technology for internal curing provides additional water pockets inside the concrete, enhancing the reaction between the cement and water, which adds to strength and durability. This new technology is enabling Indiana to improve bridges in the state with a new “internally cured” high-performance concrete.

-

-

Novel nanosized antenna arrays key to effective harvesting of solar energy

For years, scientists have studied the potential benefits of a new branch of solar energy technology that relies on incredibly small nanosized antenna arrays that are theoretically capable of harvesting more than 70 percent of the sun’s electromagnetic radiation and simultaneously converting it into usable electric power. A novel fabrication technique could provide the breakthrough technology scientists have been looking for to improve today’s solar energy systems.

-

-

Exploring asteroids for commercial metal harvesting

Deep Space says that in a decade, it will be harvesting asteroids for metals and other building materials, to construct large communications platforms to replace communications satellites, and later solar power stations to beam carbon-free energy to consumers on Earth. “More than 900 new asteroids that pass near Earth are discovered every year. They can be like the Iron Range of Minnesota was for the Detroit car industry last century,” says the company’s CEO.

-

- All

- Regional

- Water

- Biometrics

- Borders/Immig

- Business

- Cybersecurity

- Detection

- Disasters

- Government

- Infrastructure

- International

- Public health

- Public Safety

- Communication interoperabillity

- Emergency services

- Emergency medical services

- Fire

- First response

- IEDs

- Law Enforcement

- Law Enforcement Technology

- Military technology

- Nonlethal weapons

- Nuclear weapons

- Personal protection equipment

- Police

- Notification /alert systems

- Situational awareness

- Weapons systems

- Sci-Tech

- Sector Reports

- Surveillance

- Transportation

Advertising & Marketing: advertise@newswirepubs.com

Editorial: editor@newswirepubs.com

General: info@newswirepubs.com

2010-2011 © News Wire Publications, LLC News Wire Publications, LLC

220 Old Country Road | Suite 200 | Mineola | New York | 11501

Permissions and Policies

Editorial: editor@newswirepubs.com

General: info@newswirepubs.com

2010-2011 © News Wire Publications, LLC News Wire Publications, LLC

220 Old Country Road | Suite 200 | Mineola | New York | 11501

Permissions and Policies