-

Timber skyscrapers may soon transform London’s skyline

The use of timber as a structural material in tall buildings is an area of emerging interest for its variety of potential benefits; the most obvious being that it is a renewable resource, unlike prevailing construction methods which use concrete and steel. The research is also investigating other potential benefits, such as reduced costs and improved construction timescales, increased fire resistance, and significant reduction in the overall weight of buildings. London’s first timber skyscraper could be a step closer to reality as city engineers are finalizing their evaluation of a conceptual plans for an 80-storey, 300-meter high wooden building integrated within the Barbican.

-

-

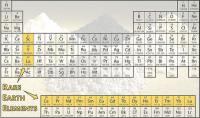

Risk and Reliance: Mineral resources and the U.S. economy

In 1954 the United States was fully reliant on foreign sources for only eight mineral commodities. In 2016, the United States was fully reliant on foreign sources for twenty mineral commodities, including rare earth elements, manganese, and niobium. This is a 250 percent increase in sixty years. China is the single largest source of mineral commodities for the United States, particularly for resources like rare earth elements, germanium, and industrial diamonds. Of the 47 mineral commodities that the United States is more than 50 percent reliant on foreign sources, 24 came in part from China.

-

-

Monitoring critical minerals to ensure national preparedness

In 2014, the Defense Logistics Agency (DLA) came to a startling conclusion: The United States needed to increase its stockpile of a basic manufacturing material with military applications — yttrium oxide, a material used in laser rangefinders. This shortfall meant that in 2014, the DLA had to submit a request to Congress to acquire new material for the National Defense Stockpile. The DLA has a watch list of about 160 materials, and economists at the agency have developed an early warning system that let them concentrate on high-priority materials.

-

-

Evaluating critical mineral-resource potential in Alaska

A new method for evaluating the resource potential for large, underexplored regions for critical minerals in Alaska is now available online. Critical minerals are used in products that are vital to national security, technology, and also play an integral role in our everyday modern life.

-

-

The challenge of sustainable mineral supply

An international team of researchers says global resource governance and sharing of geoscience data is needed to address challenges facing future mineral supply. Specifically of concern are a range of technology minerals, which are an essential ingredient in everything from laptops and cell phones to hybrid or electric cars to solar panels and copper wiring for homes. However, base metals like copper are also a matter of immense concern.

-

-

New material helps fight against hospital-acquired infections

Researchers have developed a new light-activated antimicrobial material for use in the fight against the most common hospital infections. Specifically, the new material is a molybdenum complex that has never been used before in antimicrobial photodynamic therapy (PDT).

-

-

Cleaning concrete contaminated with chemicals

In March 1995, members of a Japanese cult released the deadly nerve agent sarin into the Tokyo subway system, killing a dozen people and injuring a thousand more. This leads to the question: What if a U.S. transportation hub was contaminated with a chemical agent? The hub might be shut down for weeks, which could have a substantial economic impact. Craig Tenney, a chemical engineer at Sandia National Laboratories, is looking for better ways to clean contaminated concrete to reduce that impact.

-

-

How building design changed after 9/11

When buildings collapse killing hundreds – or thousands – of people, it’s a tragedy. It’s also an important engineering problem. For structural engineers like me, that meant figuring out what happened, and doing extensive research on how to improve buildings’ ability to withstand a terrorist attack. Research has found ways to keep columns and beams strong even when they are stressed and bent. This property is called ductility, and higher ductility could reduce the chance of progressive collapse. Mixing millions of high-strength needle-like steel microfibers into concrete – to prevent the spreading of any cracks that occur because of an explosion or other extreme force – creates material which is superstrong and very ductile. This material, called ultra-high-performance fiber-reinforced concrete, is extremely resistant to blast damage. As a result, we can expect future designers and builders to use this material to further harden their buildings against attack. It’s just one way we are contributing to the efforts to prevent these sorts of tragedies from happening in the future.

-

-

Recovering rare-earth magnets from used hard drives

The world’s most powerful magnets are manufactured using rare earth elements such as neodymium. These magnets are essential to the operation of everything from computer hard drives to electric and hybrid vehicles, electric bicycles, wind turbines, cell phones, air conditioners, and other appliances and industrial equipment. Need for the element is rising as demand for consumer products and clean energy technologies grows – but more than 95 percent of worldwide production of neodymium occurs outside the United States, mostly in China. A process developed at Oak Ridge National Laboratory for large-scale recovery of rare earth magnets from used computer hard drives will soon undergo industrial testing.

-

-

Huge helium discovery in Tanzania is “a life-saving find”

Helium does not just make your voice squeaky — it is critical to many things we take for granted, including MRI scanners in medicine, welding, industrial leak detection, and nuclear energy. However, known reserves are quickly running out. Until now helium has never been found intentionally — being accidentally discovered in small quantities during oil and gas drilling. Researchers have developed a new exploration approach, and the first use of this method has resulted in the discovery of a world-class helium gas field in Tanzania.

-

-

New alloy to boost rare-earth elements production

Rare earths are a group of elements critical to electronics, alternative energy, and other modern technologies. Modern windmills and hybrid autos, for example, rely on strong permanent magnets made with the rare earth elements neodymium and dysprosium. Yet there is no production occurring in North America at this time. Researchers have developed aluminum alloys that are both easier to work with and more heat tolerant than existing products. The alloys — which contain cerium — have the potential to jump-start the U.S. production of rare earth elements.

-

-

Appalachian coal ash rich in rare earth elements

In the wake of a 2014 coal ash spill into North Carolina’s Dan River from a ruptured Duke Energy drainage pipe, the question of what to do with the nation’s aging retention ponds and future coal ash waste has been a highly contested topic. A study of the content of rare earth elements in U.S. coal ashes shows that coal mined from the Appalachian Mountains could be the proverbial golden goose for hard-to-find materials critical to clean energy and other emerging technologies.

-

-

Tougher steel could be used for body armor, shields for satellites

A team of engineers has developed and tested a type of steel with a record-breaking ability to withstand an impact without deforming permanently. The new steel alloy could be used in a wide range of applications, from drill bits, to body armor for soldiers, to meteor-resistant casings for satellites.

-

-

Rare earth minerals are in short supply, so researchers seek to extract them from coal

With supplies growing scarce of essential materials needed to make products ranging from smart phones to windmills, researchers are working with academic and industry partners in a $1 million pilot project to recover rare earth elements from coal. The pilot effort is important because rare earth materials, used to create powerful permanent magnets in products as common as computer hard drives to electric motors, are in increasingly short supply, particularly heavy rare earth elements.

-

-

Extracting rare-earth elements from coal could soon be economical in U.S.

The United States could soon decrease its dependence on importing valuable rare-earth elements (REEs) which are widely used in many industries, according to a team of researchers. who found a cost-effective and environmentally friendly way to extract these metals from coal byproducts.

-

- All

- Regional

- Water

- Biometrics

- Borders/Immig

- Business

- Cybersecurity

- Detection

- Disasters

- Government

- Infrastructure

- International

- Public health

- Public Safety

- Communication interoperabillity

- Emergency services

- Emergency medical services

- Fire

- First response

- IEDs

- Law Enforcement

- Law Enforcement Technology

- Military technology

- Nonlethal weapons

- Nuclear weapons

- Personal protection equipment

- Police

- Notification /alert systems

- Situational awareness

- Weapons systems

- Sci-Tech

- Sector Reports

- Surveillance

- Transportation

Advertising & Marketing: advertise@newswirepubs.com

Editorial: editor@newswirepubs.com

General: info@newswirepubs.com

2010-2011 © News Wire Publications, LLC News Wire Publications, LLC

220 Old Country Road | Suite 200 | Mineola | New York | 11501

Permissions and Policies

Editorial: editor@newswirepubs.com

General: info@newswirepubs.com

2010-2011 © News Wire Publications, LLC News Wire Publications, LLC

220 Old Country Road | Suite 200 | Mineola | New York | 11501

Permissions and Policies