-

Sustainable Supply of Rare Earth Minerals Key to Low-Carbon Energy Future

The global low-carbon revolution could be at risk unless new international agreements and governance mechanisms are put in place to ensure a sustainable supply of rare minerals and metals, a new study has warned.

-

-

What Causes Steel Corrosion in Reinforced Concrete

Since the Egyptian pyramids and the Roman Coliseum were built, mankind has been searching for an affordable, versatile building material, that can be easily manufactured and transported, and, above all, which is durable. Concrete has all these characteristics, but there is a problem: the corrosion of steel bars that internally strengthen structures made of reinforced concrete. This situation causes rapid, internal deterioration of frames and may even lead to buildings collapsing.

-

-

R&D, not Greenland, Can Solve Our Rare Earth Problem

While President Trump’s proposal to buy Greenland lit up social media feeds and left many scratching their heads, people who work on rare earth elements were not surprised. Greenland has rare earth elements, and currently most are mined in China. Julie Michelle Klinger and Roger Turner write that instead of periodically reviving rare earth scarcity myths to stoke anti-China sentiment or justify outlandish ideas like buying Greenland or pulverizing the moon, we can invest in several areas where people are already working. “Opening more mines like it’s 1590, buying territories like it’s 1867, or blasting asteroids like we’re in a 1950s sci-fi flick won’t solve the problem, because the problem is not a shortage of unrefined ores. Instead, smart R&D investments will bring our production, consumption and disposal practices into the 21st century. This means reducing waste, increasing recycling and repair, and cleaning up the dirtiest and most dangerous aspects of the supply chain.”

-

-

U.S. and Australia Team Up against China's Dominance in Rare Earths

An Australian rare-earth producer has enlisted an American partner to help it chip away at China’s dominance in supplying minerals that are crucial to making smartphones, missiles, batteries for electric vehicles and a long list of high-tech products. China has used its rare-earth dominance as a weapon in previous trade disputes and has signaled that it could do so again in its current fight with the U.S.

-

-

China's War Chest of Rare Earth Patents Give an Insight into Total Domination of the Industry

China is strengthening its grip on the rare earths supply chain and could use its dominant position as a bargaining chip in its trade war with the U.S. China has been investing heavily on facilities to do the bulk of the dirty and environmentally damaging mining and ore processing work for the world, systematically turning its know-how and methodologies into patents that could give it a competitive edge against its rivals. As of October, China had filed for 25,911 patents on all the rare earth elements, far ahead of 9,810 by the US, 13,920 by Japan and 7,280 by the European Union since 1950 when the first U.S. filing was made.

-

-

Gallium: China Tightens Grip on Wonder Metal

Did you know that a 5G base station can be squeezed into a casing the size of a shoebox? It’s thanks to gallium, a soft, bluish metal that makes it possible. The chipsets that generate powerful bursts of high frequency radio waves are not made with silicon, but gallium nitride. Gallium is one of the 35 technology-critical elements listed by the U.S. government as a national security concern. Like rare earths, the global supply of gallium is under Chinese control. China produced 390 tons of raw gallium last year, or more than 95 percent of the world output, according to the United States Geological Survey.

-

-

Timber Skyscrapers Can Rewind the Carbon Footprint of the Concrete Industry

Recent innovations in engineered timber have laid the foundations for the world’s first wooden skyscrapers to appear within a decade, a feat that is not only achievable, but one they hope will beckon in an era of sustainable wooden cities, helping reverse historic emissions from the construction industry.

-

-

Mining the future

China is set to dominate the next Industrial Revolution. A fight between the United States and China is brewing over 5G and the question of who can be trusted to control the world’s wireless infrastructure. But scant attention is being paid to an issue of arguably greater importance to the future of the world’s economy and security: China’s control of the raw materials necessary to the digital economy. No new phone, tablet, car, or satellite transferring your data at lightning speed can be made without certain minerals and metals that are buried in a surprisingly small number of countries, and for which few commonly found substitutes are available. Foreign Policy analysts write in a special report that Chinese firms, operating in niche markets with limited transparency and often in politically unstable countries, have locked up supplies of these minerals and metals with a combination of state-directed investment and state-backed capital, making long-term strategic plays, sometimes at a loss. Through in-depth analysis of company reports and disclosures, mapping of deal flows, quantification of direct and indirect equity stakes, and other primary research, FP Analytics has produced the first consolidated review of this unprecedented concentration of market power. Without rhetoric or hyperbole, this fact-based analysis reveals how rapidly and effectively China has executed its national ambitions, with far-reaching implications for the rest of the world.

-

-

How China could shut down America’s defenses

Advanced U.S. weapons are almost entirely reliant on rare-earth materials only made in China—and they could be a casualty of the trade war. Keith Johnson and Lara Seligman write in Foreign Policy that President Donald Trump has often argued that China has much more to lose than the United States in a trade war, but critics say his administration has failed to address a major U.S. vulnerability: Beijing maintains powerful leverage over the war-making capability of its main strategic rival through its control of critical materials.

-

-

U.S. moves to lessen dependence on foreign-sourced rare earth materials

Critical minerals are needed for many products used by Americans in everyday life. These minerals are also used to make many other products important to the American economy and defense. The assured supply of these critical minerals is thus essential to the U.S. economic security and national defense. Currently, the United States is heavily dependent on foreign sources of critical minerals – importing more than 50 percent of the U.S. annual consumption of 31 of the 35 minerals. The U.S. relies completely on imports to supply its demand for 14 critical minerals.

-

-

China raises threat of rare-Earths cutoff to U.S.

With a simple visit to an obscure factory on Monday, Chinese President Xi Jinping has raised the specter that China could potentially cut off supplies of critical materials needed by huge swaths of the U.S. economy, underscoring growing concerns that large-scale economic integration is boomeranging and becoming a geopolitical weapon. Keith Johnson and Elias Groll write in Foreign Policy that Beijing could slam every corner of the American economy, from oil refineries to wind turbines to jet engines, by banning exports of crucial minerals.

-

-

Better earthquake protection for buildings

Researchers examine how buildings with externally bonded fiber-reinforced polymer composite retrofits withstood the 30 November 2018 magnitude 7.1 earthquake in Alaska. By assessing how these buildings held up, the researchers hope to help engineers construct buildings that stand up to natural disasters.

-

-

A Seattle quake may cause more damage than expected to reinforced concrete

Using ground motions generated for a range of simulated magnitude 9 earthquakes in the Pacific Northwest, researchers are testing how well reinforced concrete walls might stand up under such seismic events. The walls may not fare so well, especially within the city of Seattle, the researchers say.

-

-

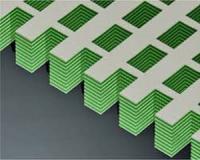

“Metamaterials” may mitigate earthquake damage

In the past decade scientists have been experimenting with metamaterials, artificial materials designed with periodic internal structures to give them properties not found in natural materials. Some of these materials can control waves propagating through them, filtering sound or deflecting light so that an object appears “cloaked” or invisible, for instance. Could this same principle be applied to controlling seismic waves?

-

-

Detecting rare metals used in smartphones

A more efficient and cost-effective way to detect lanthanides, the rare earth metals used in smartphones and other technologies, could be possible with a new protein-based sensor that changes its fluorescence when it binds to these metals.

-

- All

- Regional

- Water

- Biometrics

- Borders/Immig

- Business

- Cybersecurity

- Detection

- Disasters

- Government

- Infrastructure

- International

- Public health

- Public Safety

- Communication interoperabillity

- Emergency services

- Emergency medical services

- Fire

- First response

- IEDs

- Law Enforcement

- Law Enforcement Technology

- Military technology

- Nonlethal weapons

- Nuclear weapons

- Personal protection equipment

- Police

- Notification /alert systems

- Situational awareness

- Weapons systems

- Sci-Tech

- Sector Reports

- Surveillance

- Transportation

Advertising & Marketing: advertise@newswirepubs.com

Editorial: editor@newswirepubs.com

General: info@newswirepubs.com

2010-2011 © News Wire Publications, LLC News Wire Publications, LLC

220 Old Country Road | Suite 200 | Mineola | New York | 11501

Permissions and Policies

Editorial: editor@newswirepubs.com

General: info@newswirepubs.com

2010-2011 © News Wire Publications, LLC News Wire Publications, LLC

220 Old Country Road | Suite 200 | Mineola | New York | 11501

Permissions and Policies