EnergyNew biorenewables technology about to reach the marketplace

Innovative technology provides a new way to transform cellulosic biomass into renewable fuels and high-value chemicals; ,the technology uses ionic liquids to break down cellulosic or non-food plant biomass without using enzymes or costly pretreatment steps

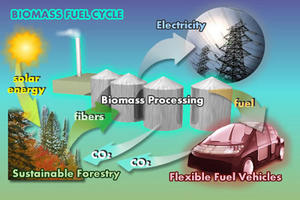

Illustration of the biomass fuel cycle // Source: mtu.edu

A licensing agreement for a novel renewable chemical and biofuel production method between Hyrax Energy and the Wisconsin Alumni Research Foundation (WARF) promises to accelerate commercial development of the technology and lead to high-quality U.S. jobs.

Developed in the laboratory of Ron Raines, a University of Wisconsin–Madison biochemistry professor and a Hyrax founder, the technology provides a new way to transform cellulosic biomass into renewable fuels and high-value chemicals. A University of Wisconsin, Madison release reports that the chemical process, developed with support from the Great Lakes Bioenergy Research Center on the UW–Madison campus, uses ionic liquids to break down cellulosic or non-food plant biomass without using enzymes or costly pretreatment steps.

The company’s process creates fermentable sugars, which can be converted into a variety of important chemicals, including fuels and plastics.

“Gaining this licensing agreement for the patent-pending technology allows the company to move forward with its business plan for implementing the technology on a commercial scale,” Raines said. “The combination of the license for this technology and Hyrax’s own intellectual property outlines a clear path toward delivering high-value products to a diverse customer base.”

Jennifer Gottwald, a licensing manager for WARF who specializes in clean technologies, said the agreement highlights the ways in which university research drives commercial innovation and creates benefits for society.

“Using waste materials such as corn stover and forestry byproducts, society may now have a way to produce high-value fuels and chemicals that improve the efficiency of the agricultural industry while reducing our nation’s reliance on imported fossil fuels,” she said.

The process developed in the lab avoids the need for costly pretreatment efforts typically used to overcome key problems with biomass including its water-insolubility and resistance to molecular deconstruction. The technology avoids these problems by employing ionic liquids to dissolve raw biomass from the beginning.

“Doing the entire conversion process in ionic liquids eliminates enzymes, pretreatment steps and harsh energy inputs and leads to a dramatic reduction in process complexity and capital intensity,” Raines said.

Coupled with its scientific significance, the licensing of the new technology marks a major step toward commercializing this approach to biofuel production on an industrial scale.

“Hyrax has done considerable market research into the cost of ionic liquids and developed a process model that has been validated by third parties. The economic advantages of this approach far outweigh the costs,” Raines said. “We have been fortunate to have the support of the Great Lakes Bioenergy Research Center and WARF Accelerator Program to fund development of the technology and provide the intellectual property protection necessary to support the process of commercialization.”