Infrastructure protectionMan-induced quakes to help in building safer, sturdier buildings

A team led by Johns Hopkins structural engineers is shaking up a building in the name of science and safety. Using massive moving platforms and an array of sensors and cameras, the researchers are trying to find out how well a two-story building made of cold-formed steel can stand up to a lab-generated Southern California quake.

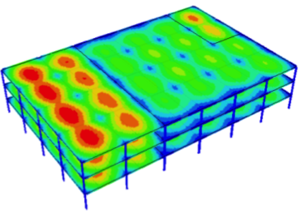

Model shows areas of comparative stress during an earthquake // Source: jhu.edu

Earthquakes never occur when you need one, so a team led by Johns Hopkins structural engineers is shaking up a building themselves in the name of science and safety.

Using massive moving platforms and an array of sensors and cameras, the researchers are trying to find out how well a two-story building made of cold-formed steel can stand up to a lab-generated Southern California quake. A Johns Hopkins University release reports that the testing, taking place at the University at Buffalo’s earthquake engineering research center, marks the culmination of a 3-year, $1 million research project involving scientists from six universities and design consultants from the steel industry. The work is taking place in the only facility in the United States that is capable of replicating an earthquake in three directions beneath a building measuring 50 feet long, 20 feet wide, and 20 feet tall. The trials will wrap up in mid-August when the researchers will shake the unoccupied structure with forces comparable to those at the epicenter of the catastrophic 1994 Northridge earthquake in Los Angeles, which claimed dozens of lives and caused billions of dollars in damage.

The researchers may sound like a wrecking crew, but their work has important implications for the people who construct, live or work in buildings. The results are expected to lead to improved nationwide building codes that will make future cold-formed steel buildings less expensive to construct than current ones. Also, the new codes could, in certain cases, make lightweight cold-formed steel buildings less costly to construct than those made of materials such as timber, concrete or hot-rolled steel. In earthquake-prone regions, these code updates should help structural designers and builders reduce the likelihood of a costly and life-threatening building collapse. Finally, the research, funded primarily by the National Science Foundation (NSF), with added support from the steel industry, could lead to broader use of building components made of environmentally friendly cold-formed steel, made of 100 percent recycled steel.

Cold-formed steel pieces, commonly used to frame low- and mid-rise buildings, are made by bending sheet metal, roughly one-millimeter-thick, into structural shapes without using heat.

Cold-formed steel already has been used in an array of structures such as college dorms, assisted living centers, small hotels, barracks, apartments, and office buildings. Although the material is popular, some large knowledge gaps exist regarding how well cold-formed steel structures will stand up to extreme conditions — including earthquakes. This has