Personal protection equipmentStrongest-ever nano-material developed

Israeli scientists develop a revolutionary new ball-shaped nanostructure — fully derived from very simple organic elements yet strong as steel; potential uses of the nanotechnology include bullet-proof vests, medical implants, space, and aviation applications

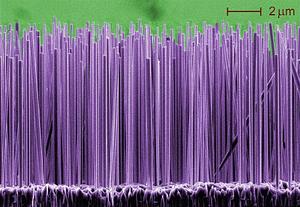

Organic nanostructures capable of conducting electricity // Source: ecofuss.com

A revolutionary new ball-shaped nanostructure — fully derived from very simple organic elements yet strong as steel — has been developed and characterized at the laboratories of Professor Ehud Gazit of Tel Aviv University, Dr. Itay Rousso and Nitzan Kol of the Weizmann Institute of Science in Rehovot, and David Barlam and Roni Shneck atBen-Gurion University of the Negev in Beersheba.

These promising bio-inspired nanospheres have many potential uses — from durable composite materials and bullet-proof vests to medical implants that are not metallic and reinforced plastics for tooth implants. They could also be used in the space, aviation, and transportation industries.

The groundbreaking work has just been published in Wiley-VCH’s leading journal Angewandte Chemie.

Organic nanostructures are key elements of nanotechnology because these building blocks can be made with tailored chemical properties. Their disadvantage has been that their mechanical properties have so far been significantly inferior to those of metallic nanostructures. But the Israeli team managed to produce biocomposite nanospheres that are as rigid as metal.

Judy Siegel-Itzkovich writes that the team used a simple dipeptide, a molecule consisting of only two amino acids, to form spherical nanostructures. They assembled themselves into the first bio-inspired nanomaterial known to date — and without any heating or manipulation. The material is mechanically equal and even superior to many metallic substances, they said.

While demonstrating chemical properties similar to those of the ultra-rigid Kevlar polymer, already used for bullet-proof vests, the new substance is built from much simpler building blocks, enabling some important advantages: manipulation and deposition at the nanoscale, the fabrication of nano-materials of tubular, spherical and other geometres, and spontaneous formation by self-assembly.

Thus, said the team, it is a perfect building block for numerous applications.

Using an atomic force microscope, the scientists examined the mechanical properties of their nanospheres.

This device uses a nanotip (cantilever), a tiny flexible lever arm with a very fine tip at the end. When the tip is pressed against a sample, the deflection of the lever indicates whether the tip of the needle can press into the sample object, and how far in it can go. A metal needle was not able to make any impression on the nanospheres; only a needle made of diamond was able to do it.

Siegel-Itzkovich writes that the researchers used these measurements to calculate the elasticity modulus for the nanospheres, which is a measure of the material’s stiffness. The larger the value, the more resistance a material has to its deformation. By using a high-resolution scanning electron microscope equipped with a nanomanipulator, it was possible to directly observe the deformation of the spheres.

The new nanotechnology development now emerging from Tel Aviv University is based on extensive research which began in Gazit’s laboratory seven years ago. In an earlier achievement, the team was able to fabricate tubular nanostructures that assemble themselves into vast “forests” featuring exceptional mechanical and physical properties. This earlier work, based on the doctoral thesis of Dr. Lihi Adler-Abramovich and published last year in the prestigious journal Nature Nanotechnology, may eventually generate self-cleaning windows and solar panels, as well as supreme energy storage devices with exceptionally.

—Read more in Lihi Adler-Abramovich et al., “Self-Assembled Organic Nanostructures with Metallic-Like Stiffness,” Angewandte Chemie (28 SEP 2010) (DOI: 10.1002/anie.201002037) (sub. req.)